Electric Heaters

The Neptronic electric heater is manufactured using the most advanced technologies available. The duct heaters are available for all applications from HVAC system VAV box, fan coil units, load banks testing, make-up air handlers, process air heaters, transport/railcar/marine.

For more details please contact +974 31100354 , info@maven-trading.com

Our Sub Product

- Open Coil Electric Heaters

- Tubular Electric Heaters

- Open Coil Electric Heaters

- Recommendations

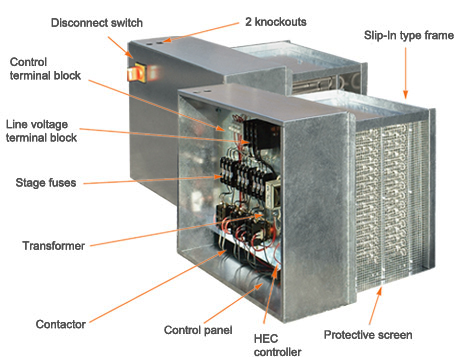

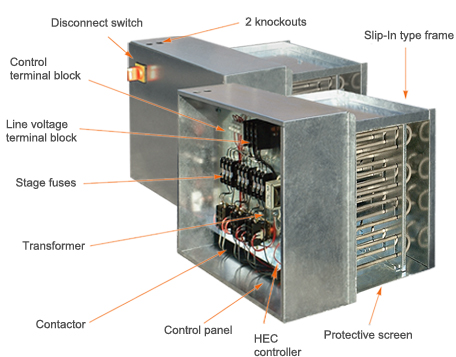

Open Coil Electric Heaters

Open Coil

- Excellent Heat Dissipation

- Minimal pressure drop

- Fast response time

- Up to 40kW / sq.ft.

Open Coil Electric Heaters

- Most popular in the industry

- Suitable for most standard HVAC ducted systems

- Heating capacities from 0.5 to 1000kW (larger loads also available)

- Up to 40kW per sq.ft

- Integrated HEC controller

- Patented EAS (Electronic Airflow Sensors)

Open Coil Elements Options

- 4Grade C NiCr60 (60% Nickel and 16% Chrome)

- 4Grade A NiCr80 (80% Nickel and 20% Chrome)

Recommendations

For applications in a humid environment, we recommend the optional NiCr 80 (grade A) elements. They are composed of 80% Nickel and 20% Chrome (does not contain iron). This will allow a maximum operating temperature of 2,100o F (1,150o C) and installation where condensation may be present in the air duct.

- Tubular and Finned Tubular

- Overview

- Advantages

- Tubular vs Finned Tubular

Tubular and Finned Tubular

- Less sensitive to humidity and dust

- Suited for demanding environments

- Excellent mechanical resistance

- Heating element not in direct contact with air

Overview

- Up to 13 kW per sq.ft. (Tubular)

- Up to 15 kW per sq.ft. (Finned Tubular)

- Tubular Elements: -Incoloy 840 (Nickel alloy)-Stainless Steel 316L (optional)

- Finned Tubular Elements: -Steel tubes with Steel fins -Stainless Steel 316L tubes with Stainless Steel 304 fins (optional)

Heating elements not in direct contact with air Element of U or W shape:

Advantages

The Tubular and Finned Tubular heater type offers an excellent mechanical resistance, suited for demanding environments. These elements are less sensitive to humid and dusty environments but offer a slower response time.

Tubular vs Finned Tubular

- Incoloy 840 (Nickel alloy)

- Stainless Steel (optional) tube with a diameter of 7/16" (11mm) with heating coil in magnesium oxide powder

- Tubular Elements: -Incoloy 840 (Nickel alloy)-Stainless Steel 316L (optional)

- Steel or stainless steel (optional) tubes, with fins installed on the tube to allow a higher heat dissipation capacity.